Offshore Engineering

No two projects are alike. From icebergs in the North Atlantic to typhoons in the shallow seas off the coast of Vietnam to hurricanes in the deep waters of the Gulf of Mexico, SOFEC has a customized solution for you.

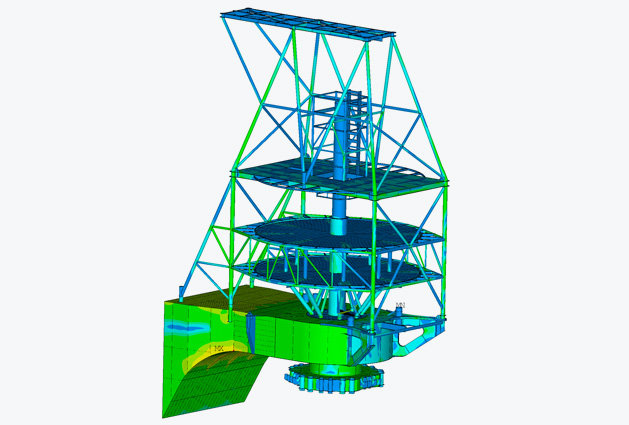

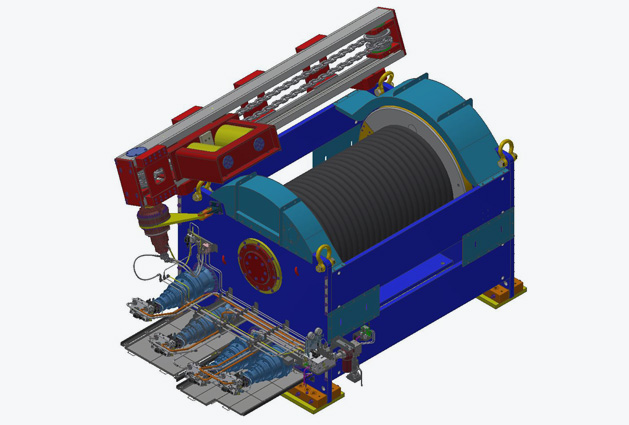

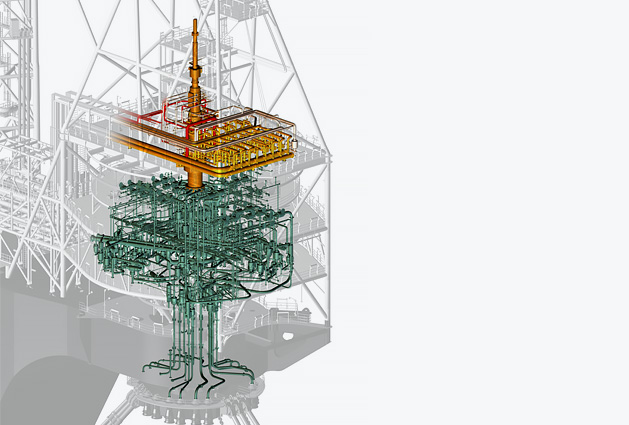

Our engineers produce some of the most complex spread and single-point mooring systems for the world’s offshore energy industry operating at greater depths, further offshore, and in harsher environments. Our engineering designs leverage our 40+ years of track record with single point mooring systems, and our continuous improvement processes help deliver reliable, low maintenance mooring systems.

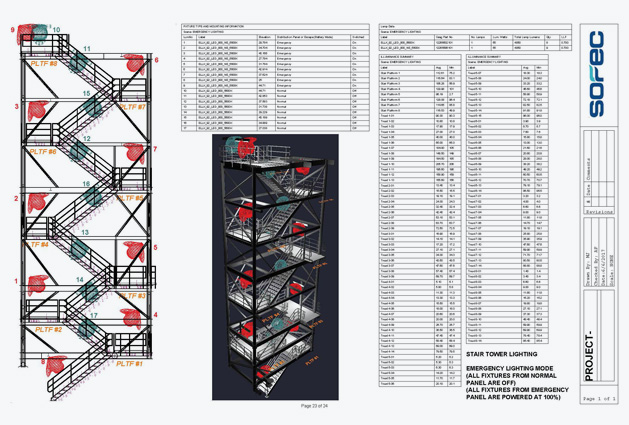

By routinely carrying out formal safety and reliability assessments, our engineers detect, control, and mitigate health, safety, and environmental risks associated with its marine terminals and floating systems. Our broad engineering expertise and experience brings efficiency to the process and superior reliability to our products.

SOFEC’s engineering group consists of five major discipline specific groups.